SPECIFICATIONS and Grades

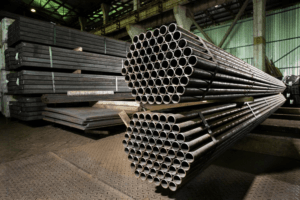

Dimensions We Offer:

We manufacture steel pipes and tubes in the following dimensions to meet a variety of industrial requirements:

- Outer Diameter (OD): 4mm to 42mm

- Wall Thickness (W.T.): 0.5mm to 4mm

1. DIN 2391 (Cold Drawn Seamless Steel Tubes)

Description:

DIN 2391 is a standard for cold-drawn precision seamless steel tubes. These tubes are known for their tight tolerances and high quality, making them suitable for applications that demand superior mechanical properties. DIN 2391 pipes are primarily used in hydraulic, pneumatic, and other mechanical applications where precise dimensions and high strength are essential.

Chemical Composition:

-

- Carbon (C): 0.10% – 0.20%

-

- Manganese (Mn): 0.30% – 0.60%

-

- Phosphorus (P): ≤ 0.025%

-

- Sulfur (S): ≤ 0.025%

-

- Silicon (Si): 0.10% – 0.35%

-

- Copper (Cu): ≤ 0.35%

Mechanical Properties:

-

- Tensile Strength: 430-650 MPa

-

- Yield Strength: 250 MPa

-

- Elongation: ≥ 30% (in 50mm)

Applications:

-

- Hydraulic cylinders

-

- Pneumatic systems

- Automotive and engineering applications requiring high precision

2. St 52 (Structural Steel)

Description:

St 52 is a high-strength, low-alloy structural steel used in various mechanical and structural applications. It offers excellent weldability, formability, and machinability, which makes it suitable for manufacturing large mechanical structures, automotive components, and other machinery.

Chemical Composition:

- Carbon (C): 0.22% – 0.24%

- Manganese (Mn): 1.30% – 1.60%

- Phosphorus (P): ≤ 0.035%

- Sulfur (S): ≤ 0.035%

- Silicon (Si): 0.40% – 0.70%

- Chromium (Cr): ≤ 0.30%

- Nickel (Ni): ≤ 0.30%

Mechanical Properties:

- Tensile Strength: 490-630 MPa

- Yield Strength: 355 MPa

- Elongation: ≥ 22% (in 50mm)

Applications:

- Heavy machinery and construction equipment

- Structural elements in engineering and construction

- Automotive parts

3. SA 179 (Seamless Carbon Steel Tubes for Heat Exchangers)

Description:

SA 179 is a specification for seamless carbon steel tubes, primarily used in heat exchangers, condensers, and other heat transfer equipment. These tubes offer excellent performance in high-temperature applications and are known for their good resistance to oxidation and corrosion.

Chemical Composition:

- Carbon (C): 0.06% – 0.12%

- Manganese (Mn): 0.27% – 0.63%

- Phosphorus (P): ≤ 0.035%

- Sulfur (S): ≤ 0.035%

- Silicon (Si): 0.10% – 0.35%

Mechanical Properties:

- Tensile Strength: 415-550 MPa

- Yield Strength: 205 MPa

- Elongation: ≥ 40% (in 50mm)

Applications:

- Heat exchangers

- Boilers

- Condensers

- Other high-temperature applications requiring reliable thermal conductivity

4. SAE 1005 (Low Carbon Steel)

4. SAE 1005 (Low Carbon Steel)

Description:

SAE 1005 is a low-carbon steel alloy that offers excellent machinability, formability, and weldability. It is often used in applications where moderate strength is sufficient, and where ease of processing is required. It is commonly used in automotive manufacturing and light structural applications.

Chemical Composition:

- Carbon (C): 0.05% – 0.10%

- Manganese (Mn): 0.30% – 0.60%

- Phosphorus (P): ≤ 0.04%

- Sulfur (S): ≤ 0.05%

- Silicon (Si): 0.10% – 0.30%

Mechanical Properties:

- Tensile Strength: 330-480 MPa

- Yield Strength: 170 MPa

- Elongation: ≥ 37% (in 50mm)

Applications:

- Automotive components

- Structural elements

- Electrical applications (wires, cables)

- Light fabrication